At Orla Studios, we see mass timber as more than a building material—it is a framework for designing sustainable, human-centered architecture. Our architectural project, the Mass Timber Winery, now under construction in Napa Valley, embodies the principles and best practices of designing with this extraordinary material. Below, we share an in-depth guide to approaching mass timber design, from concept to construction.

Understanding Mass Timber

Mass timber is an umbrella term for engineered wood products created by layering and bonding smaller wood elements into large structural components. The main types include:

- Cross-Laminated Timber (CLT): Layers of lumber stacked at right angles and glued together to form rigid panels ideal for walls, floors, and roofs.

- Glue-Laminated Timber (Glulam): Boards bonded lengthwise to form strong beams and columns.

- Nail- or Dowel-Laminated Timber (NLT/DLT): Lumber fastened together without adhesives, creating panels suited for decking and floors.

Each type has specific advantages, and successful projects often combine several systems.

Principles of Designing with Mass Timber

- Early Integration of Structure and Architecture

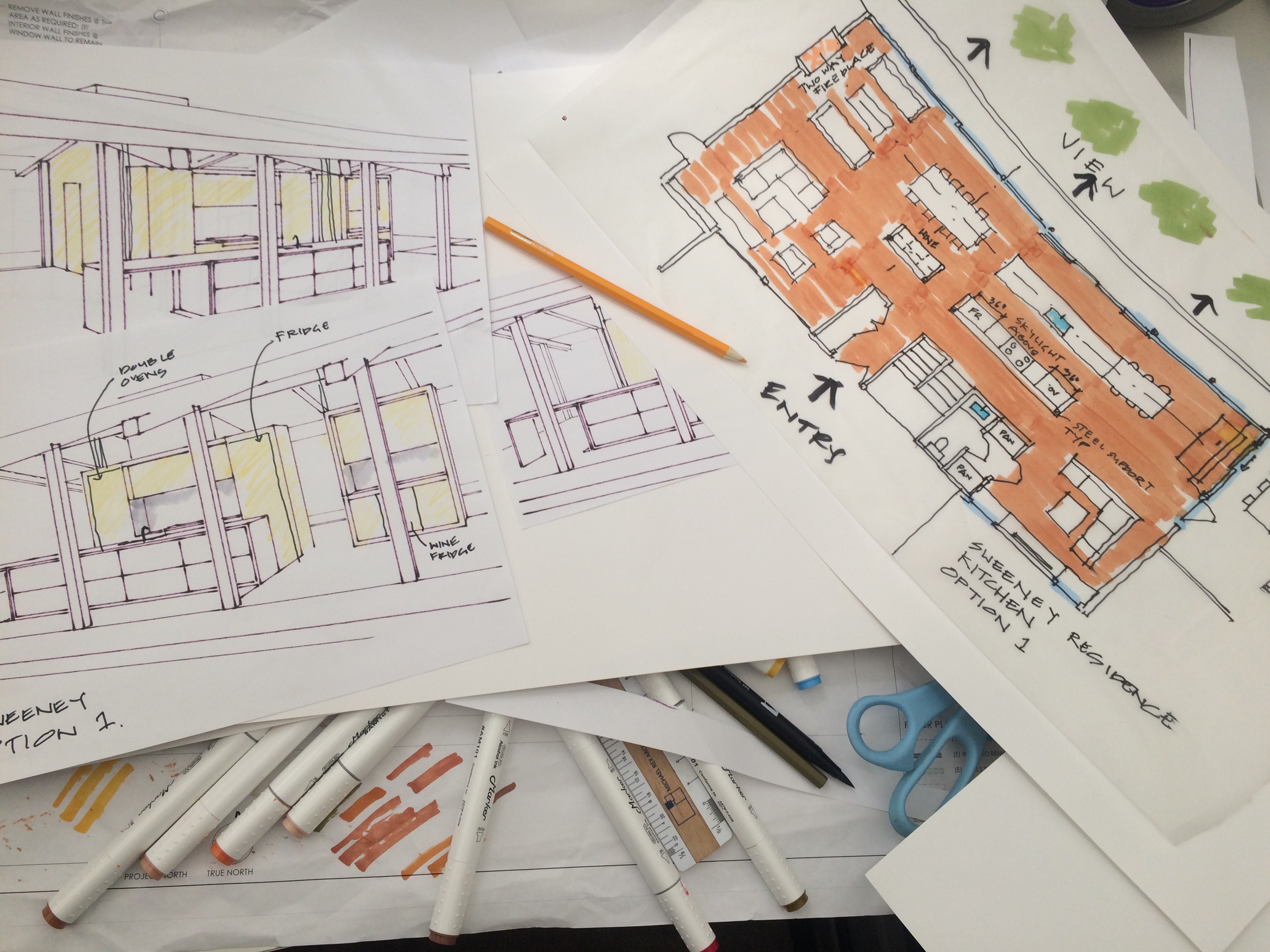

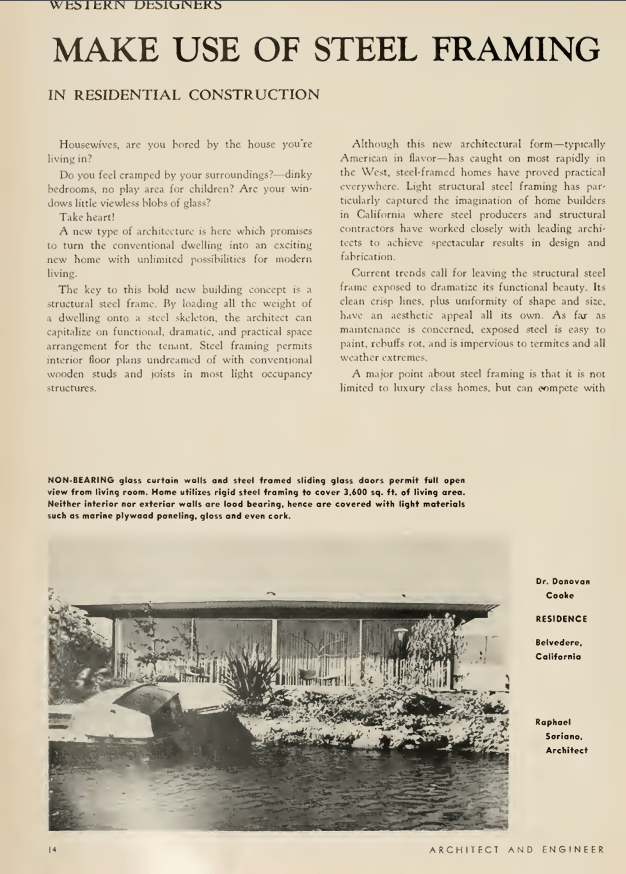

Mass timber is most successful when structural and architectural design proceed hand in hand. The size and spacing of beams, columns, and panels dictate interior proportions and aesthetics. Unlike steel or concrete, mass timber structure is often left exposed, so early design decisions directly shape the building’s character. - Modularity and Prefabrication

Mass timber panels and beams are fabricated off-site with precision CNC cutting. This allows for rapid assembly, but it requires careful planning during design. Dimensions should align with manufacturing standards, transportation limits, and crane capacities. Modular thinking reduces waste and speeds up construction. - Fire Safety Design

Despite being wood, mass timber achieves robust fire performance. Panels char at a predictable rate, forming a protective layer that insulates the structural core. Designers must account for sacrificial charring when sizing beams and panels, and coordinate closely with fire consultants and code officials. - Seismic and Structural Performance

Timber’s lightness and flexibility reduce seismic loads compared to concrete. Connections—steel plates, dowels, and screws—become critical elements of design. Careful detailing ensures both strength and ductility, particularly in taller structures or those in earthquake-prone regions. - Acoustics and Vibration Control

Mass timber’s lightness can present challenges with sound transmission and floor vibration. Solutions include layering materials (e.g., topping slabs or acoustic mats), designing for thicker panels, and integrating sound-absorbing finishes in interiors. - Moisture and Durability

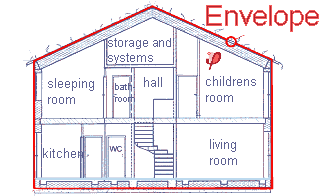

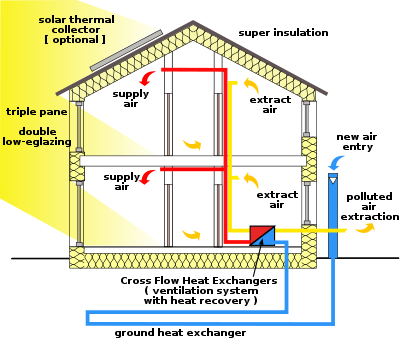

Protecting timber from prolonged moisture exposure is essential. Overhangs, rainscreens, and controlled detailing at joints prevent water infiltration. During construction, weather protection measures (temporary roofs, membranes) safeguard panels before the building envelope is complete. - Mechanical, Electrical, and Plumbing (MEP) Coordination

Because panels are prefabricated, openings for ducts, conduits, and fixtures must be carefully planned and cut before delivery. Close coordination with engineers ensures services are integrated cleanly, avoiding costly on-site modifications.

Design Opportunities with Mass Timber

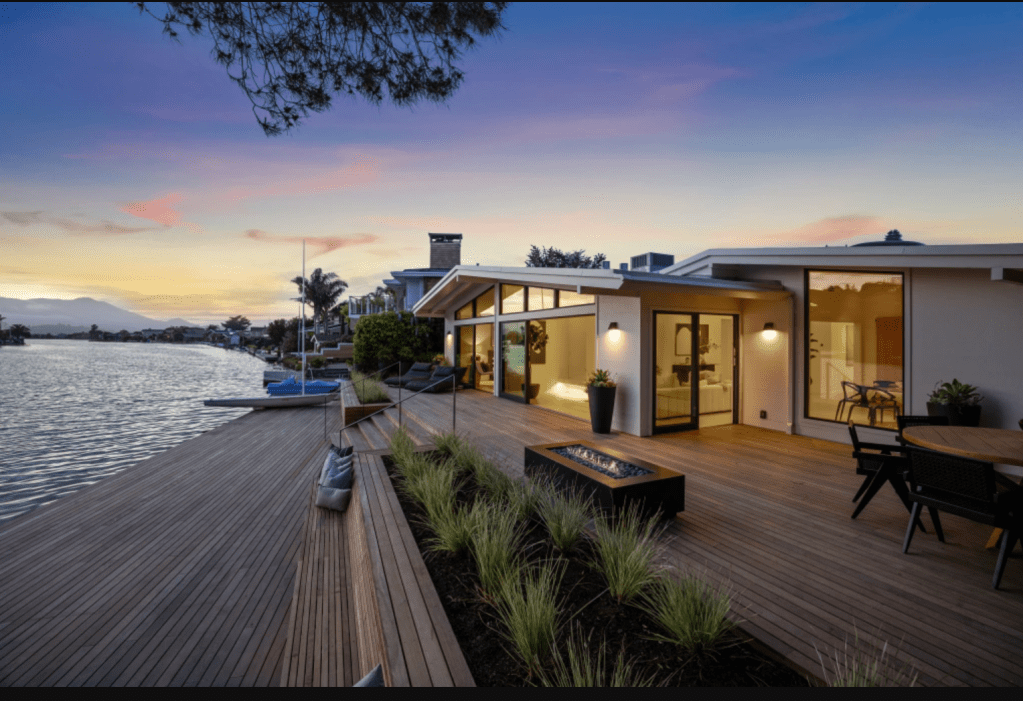

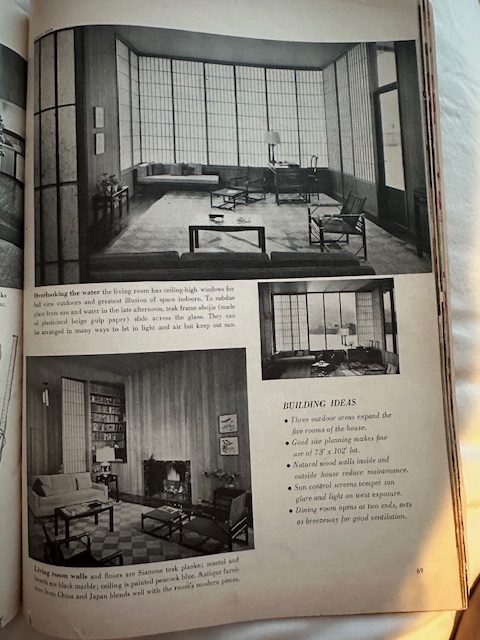

- Exposed Beauty: Unlike steel or concrete, mass timber structure is celebrated visually. Beams, columns, and ceilings can remain exposed, reducing the need for finishes and creating warm, natural interiors.

- Biophilic Design: Natural wood enhances human well-being by connecting occupants to nature, lowering stress, and improving productivity.

- Hybrid Systems: Many projects combine mass timber with steel or concrete. For example, concrete cores may house elevators and stairs while timber spans large open areas. This hybrid approach maximizes structural efficiency.

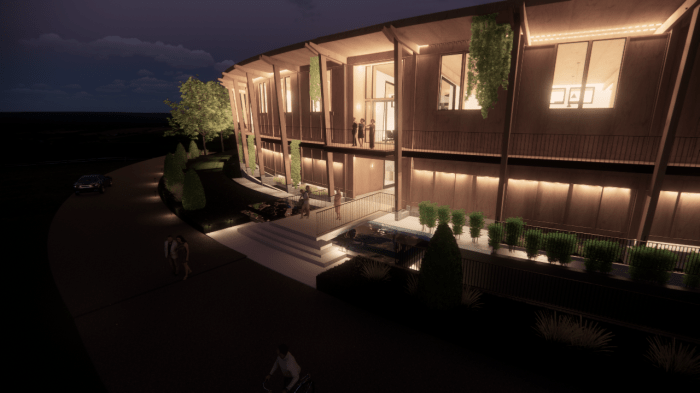

Case Study: Our Mass Timber Winery

Our Winery in Napa Valley demonstrates how these principles come together:

- Open Production Spaces: Long-span glulam beams create column-free zones for winemaking, while CLT panels form insulated, breathable roof structures.

- Hospitality and Experience: In the tasting room, exposed CLT ceilings and timber columns bring warmth and intimacy, reinforcing the winery’s connection to the vineyard landscape.

- Sustainability in Practice: The winery leverages the carbon-sequestering qualities of timber, combined with passive cooling strategies and rainwater management systems, to minimize environmental impact.

- Craft and Precision: Every joint and detail has been coordinated digitally before fabrication, ensuring a seamless on-site assembly and minimal waste.

Looking Ahead

Designing with mass timber requires a mindset shift—from linear construction sequencing to integrated, collaborative design. Architects, engineers, manufacturers, and builders must work as one team, with sustainability and precision at the core.

At Orla Studios, we are committed to advancing mass timber design across residential, commercial, and cultural projects. Our Winery project illustrates what is possible: architecture that is sustainable, resilient, and deeply connected to place. For us, mass timber is not just a material—it is a philosophy of building responsibly for the future.